Facts About Screen Printing Custom T-shirts Abilene Revealed

Everything about Screen Printing Custom T-shirts Abilene

Table of ContentsExamine This Report about Screen Printing Custom T-shirts AbileneNot known Details About Screen Printing Custom T-shirts Abilene Facts About Screen Printing Custom T-shirts Abilene UncoveredSome Of Screen Printing Custom T-shirts AbileneFacts About Screen Printing Custom T-shirts Abilene RevealedHow Screen Printing Custom T-shirts Abilene can Save You Time, Stress, and Money.

No mixing needed, cures very promptly, expensive, suitable for in-depth job. Combination of Diazo and SBQ, needs blending, general cure time is much less than Diazo, price is less than SBQ. The transparent acetate movie is positioned on the emulsion-coated mesh display carefully under a bright light which causes the solution to set and establish.Exposing the display for a particular time will certainly harden the exposed locations of the display, and the continuing to be unhardened emulsion, if any type of, will be washed away to leave a clear imprint on the display. The display is after that dried out, and if there are any touch-ups required, it will be done by the printer to make the imprint as near the original design as feasible.

The product to be printed is placed flat on the printing board, and the display on top of the material in the desired placement, all set to be published. In this step, the published layout will come to life. The screen is lowered down to the printing board. The preferred colour ink is included in the top of the display.

The ink presses via the open areas of the stencil and transfers on the underlying silk, as a result printing the layout on the product. The pattern will have offered its function once all the items are published. An unique cleaning liquid is used to remove the emulsion to recycle the mesh for producing new patterns.

Top Guidelines Of Screen Printing Custom T-shirts Abilene

There are six different kinds of display printing procedures. The most typical display printing strategy is place colour display printing.

It is much simpler to use as contrasted to various other screen printing methods. It can be an outstanding option for printing on t-shirts, coats, and hoodies, for instance. In halftone printing, single colours in slopes are published. The entire process makes use of a single colour of ink, and this colour obtains half-toned, leading to a various shade when looked at from a range.

In enhancement, it is a cost-efficient technique given that only one colour of ink is utilized. Grayscale printing is a superb approach of printing full-colour images as one colour grayscales or halftones.

Screen Printing Custom T-shirts Abilene Things To Know Before You Buy

Duotone printing uses the combination of two halftones for publishing the exact same photo with 2 colours. A black halftone is printed with black ink, and after that a 2nd halftone is printed with colour ink. This strategy resembles sepia-toned print in photography. It offers an innovative and artistic impact.

The simulated printing procedure incorporates the four-colour printing procedure with spot colour printing. Given that this method is helpful for both lighter and darker tones, it is functional and prominent with people looking to generate photorealistic print information.

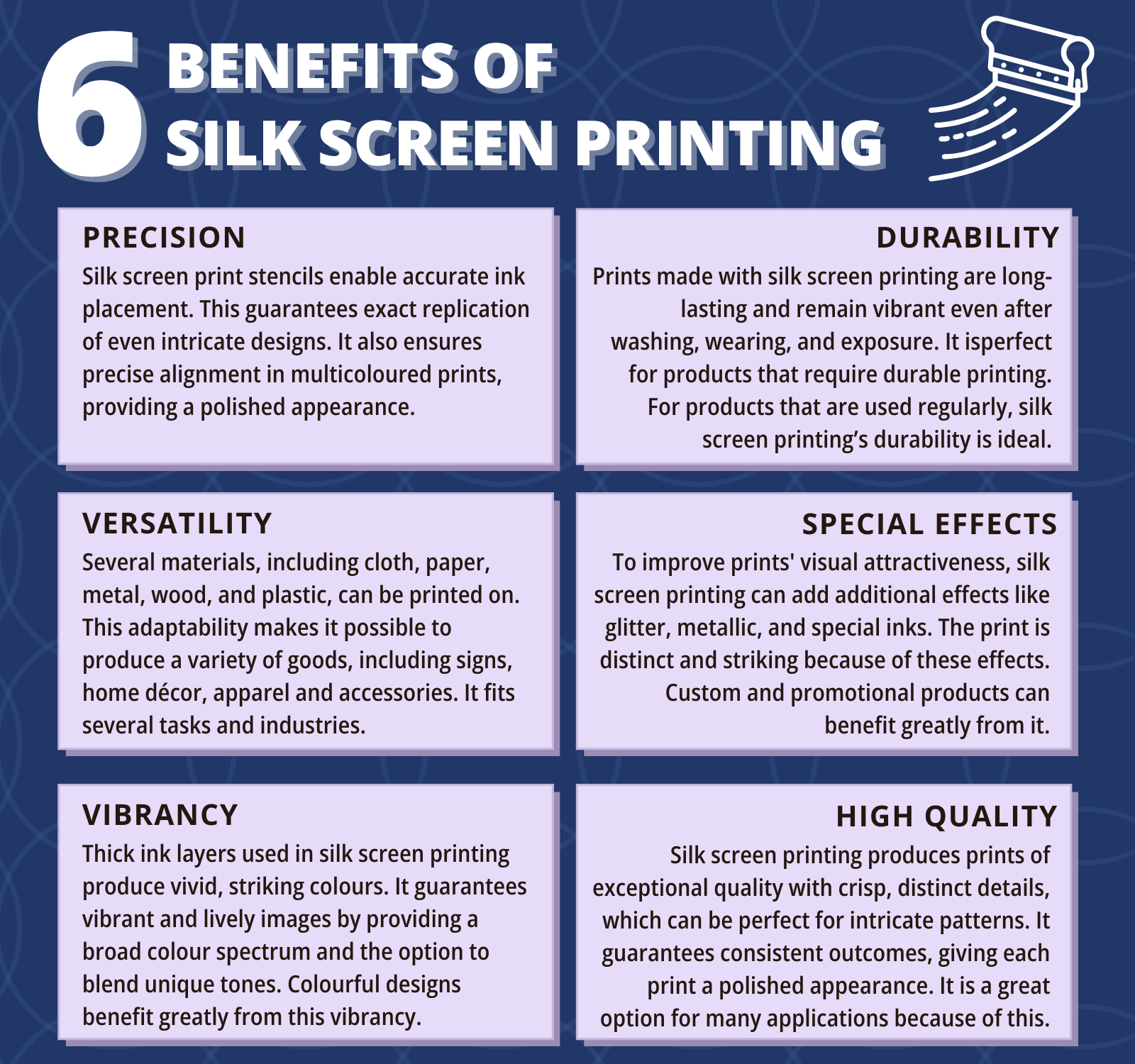

Some of these benefits include: One of the primary advantages of display printing is its versatility. Compared to other printing methods, display printing can use a heavy ink protection, resulting in a sturdy style.

Not known Details About Screen Printing Custom T-shirts Abilene

Screen printing is one of the most reliable and fast printing methods as soon as a display has been created. It is an exceptional choice if the same design is to be published over and over again (Screen Printing Custom T-Shirts Abilene). The screen printing process is relatively uncomplicated, whether it is automated or done manually. The needed devices are additionally not tough or pricey to change.

Custom screen printing is a procedure that makes use of a mesh screen to push ink in an established layout onto the material of your option. Display printing is prominent for personalized tee shirts, sweatshirts, coats, and extra. Custom-made display printed tees or other screen-printed garments are the excellent means for services to increase their brand name visibility.

The Ultimate Guide To Screen Printing Custom T-shirts Abilene

The ink's long life guarantees that prints stand up to repeated cleaning and wear, making it perfect for textiles like t-shirts, hoodies, and carryall. This method services a wide variety of surface areas, including textiles, plastics, glass, wood, and steels. Its versatility enables organizations and makers to apply designs to products like apparel, marketing products, signs, and product packaging.

Modern automated screen printing press streamline the process, enabling higher production speeds while maintaining constant quality. Automation decreases errors, guaranteeing every print equals and approximately expert requirements. Technologies like computer-to-screen (CTS) and direct-to-screen (DTS) innovations are reinventing the display printing procedure. These approaches get rid of the demand for standard film positives by electronically moving display printing designs straight onto the screen.

Getting My Screen Printing Custom T-shirts Abilene To Work

While rooted in custom, screen printing has embraced technological developments to satisfy contemporary demands. Its combination of workmanship and technology ensures it continues to be a leading option for imaginative and business printing projects. Display printing continues to be a trusted and functional printing method, offering lively colors and long lasting styles that stick out on a range of products.

For garment style that calls for a high degree of vibrancy when publishing on dark premises, display printing is still the ideal option.

Thus higher volumes can be mass generated using screen printing more rapidly and even more cost efficiently for bigger orders. Screen printing suits a broad range of materials, including plastic, material, rigid plastic, foam board, metal, glass and numerous others.